'Cargo Inspection System'

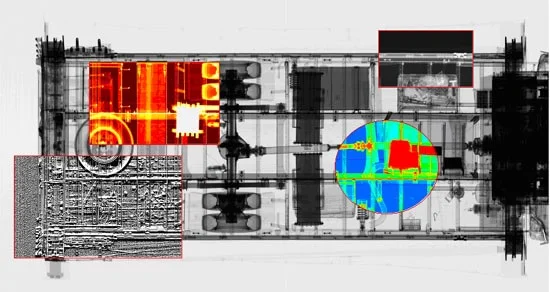

A large x-ray based cargo inspection system required the ability for operators to quickly view multiple angles of incoming cargo containers and their associated manifests to prevent contraband and weapons of mass destruction from entering the borders of the target country.

In addition to standard image manipulation tools, the client required sophisticated image processing on regions of interest for further inspection and the ability to perform complex filtering and palette processing to facilitate threat detection in a high volume processing security station. Security viewer operators would then pass/fail judgment on a cargo container as part of a larger workflow process based on the image viewing tools available in the software.

Main features include:

- Image zooming and rotation.

- Image panning, scrolling and thumbnail display through LEADTOOLS panning window with all image processing as applied to the main image.

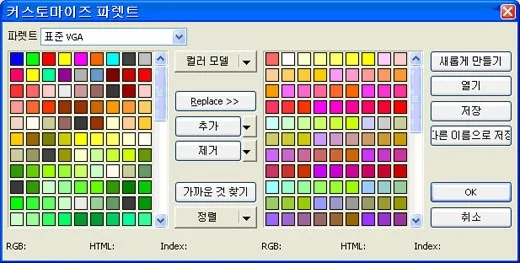

- Image palette manipulation to provide image invert, window width and level support, color palette substitution and density highlighting to call-out features in a particular image.

- LEADTOOLS provided both image filters and custom filters written for the customer.

- Support for regions of interest (ROIs, also known in LEADTOOLS as annotations) that allowed us to perform independent image processing on full image or ROI basis.

- Support for multiple image file formats and bit depths.

- Image conversions from RAW format to standard image file formats.

LEADTOOLS Palette Dialog with Korean language support

'Cargo Inspection System' was created with LEADTOOLS Medical Imaging.

"Due to an aggressive development and deployment schedule it was necessary to create the image viewing workstation software with sophisticated image processing and scanned document display without compromising either the deadline or features. By using LEADTOOLS we were able to meet those goals in relatively short order and deliver a multi-monitor based viewer. "

'X-Ray Gauge Parts Inspections'

An X-Ray based system was required to automatically inspect manufactured parts for conformance to dimensional tolerances and standards such as the location and measurements of holes or joint fittings. The characteristics of these parts are determined from 2-dimensional data generated by a hardware system using x-rays and a flat-panel assembly moving in a single plane.

Using a combination of custom image processing algorithms and third-party tools, point cloud data was gathered and compared against a template to create quality assurance reports. Some of the manufactured parts were up to 8 feet in length, and it was necessary to display the x-rayed image and the CAD based drawing across 8 monitors to display the parts in the proper proportions.

Main Features include:

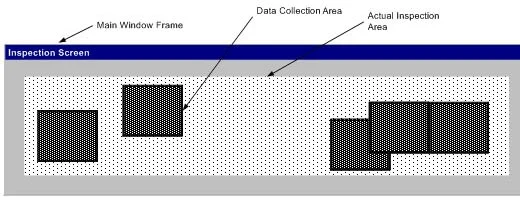

- Compound image viewing on a display surface spanning across 8 19" monitors.

- Sub-image overlays against a large canvas background.

- Proportional display with image zoom capability.

- Window width and level support for detailed inspection of areas of interest.

-Mark Bromberg, Dir of Business Development [email protected]